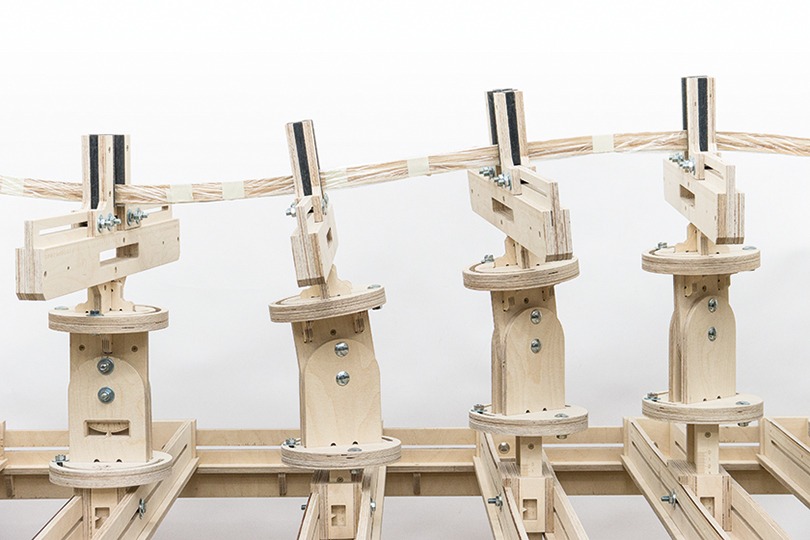

Glulam is a process where individual timber lamellas are glued together in several stages to form a curved timber beam which can have either one or two degrees of freedom. With the timber building industry and especially the Glulam process being on the rise for large scale non-standard architecture and building regulations being changed all across the globe in favor of timber construction, I found it an interesting topic to explore.

I believe that traditional craftsmanship, digital fabrication technology and design should go hand in hand and that each discipline should inform the others aswell as vice-versa. As a consequence, craftsmen, makers and designers can develop new techniques and new tools, both digital and physical aswell as hand-driven and automatic. This cross-informing between disciplines does not only lead to fully automated, computer driven machines on the one hand and updated variants of traditional handcrafting tools on the other hand but also to a form of hybrid.

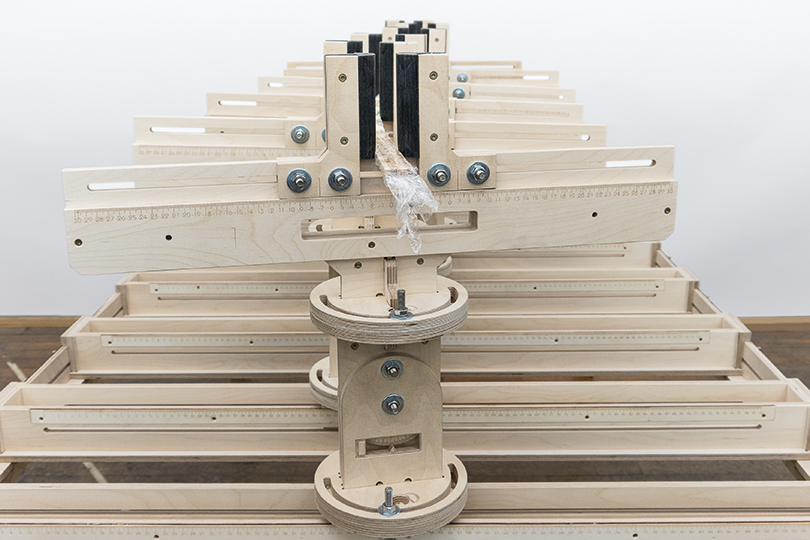

The Small Scale Glulam Tool is such a hybrid: The tool itself is entirely digitally planned and has a powerful programmed planning toolkit behind it with which the user can simulate the lamination of the desired part directly in a CAD-software. But what makes it a hybrid is the fact that every setting of the machine has to be adjusted by hand and is not supported by any electronics.

The biggest challenge was not only planning the actual tool but making it work together with the digital workflow aswell. Special geometric transformations had to be written to prepare the user's input geometry for the simulation on the glulam tool while making the digital toolkit as user friendly as possible.

The result is a prototypical planning software where the user can load a part and ends up with a digital simulation of the different lamination stages aswell as a printable setup plan which tells the user how he has adjust the tool.

I consider access to a vast variety of different manufacturing tools as absolutely critical for designers and especially design students because it allows and encourages experiments and exploration. The goal was to create such a tool - primarily to allow manufacturing of small scale glulam but also to spark interest in how it can be tuned to perform similar tasks with other materials than timber.